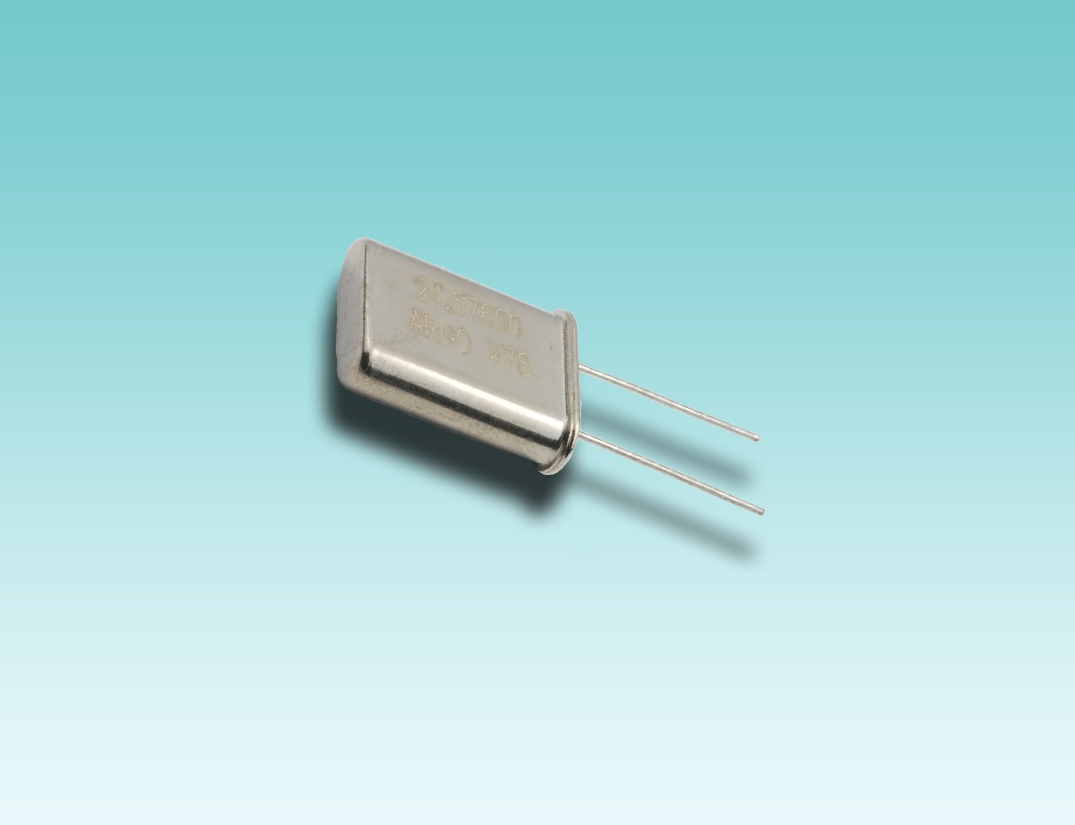

Holder Type Dip Crystal

MHz Holder Type Dip Crystal AGX-T49U, AGX-T49T / AGX-T49S / T49SS / T49S+

Equivalent Series Resistance (ESR)

| Model | AGX-T49U, AGX-T49T | AGX-T49S / T49SS / T49S+ |

| Frequency Range | 1.0 ~ 200 MHz | 3.2 ~ 70 MHz |

| Mode of Oscillation |

2.01~45.0MHz:AT-cut Fund. 24.0~100MHz: AT-cut 3rdOvertone 80.0~160MHz: AT-cut 5rd Overtone 110~200 MHz: AT-cut 7rd Overtone |

3.2~30.0MHz:AT-cut Fund. 27.0~70MHz: AT-cut 3rdOvertone 24.0~48MHz: BT- cut Fund. |

| Frequency Tolerance |

SL-cut: ±50ppm at 25ºC AT-cut: ±30ppm at 25ºC |

AT-cut: ±30ppm at 25ºC BT-cut: ±50ppm at 25ºC |

| Frequency Stability |

SL-cut: ±100ppm over -10~+70ºC AT-cut: ±50ppm over -10~+70ºC |

AT-cut: ±30ppm over -10~+70ºC BT-cut: ±100ppm over -10~+70ºC |

| Shunt Capacitance (C0) | 7pF Max. | 7pF Max. |

| Load Capacitance (CL) | 8 pF ~ 32 pF for Series | 8 pF ~ 32 pF for Series |

| Drive Level | 100 ΩW | 100 ΩW |

| Operating Temperature Range | -10 ~ +70ºC | -10 ~ +70ºC |

| Storage Temperature Range | -40 ~ +85ºC | -40 ~ +85ºC |

| Aging | Less than ±3 ppm / year. (At 25±5ºC ) | Less than ±3 ppm / year. (At 25±5ºC ) |

Equivalent Series Resistance (ESR)

| Model | Freq. MHz | Oscillation Mode | ESR Max. |

| AGX-T49U / 49T | 1.0~1.3 | SL cut | 5000 Ω |

| 2.01~3.0 | AT cut Fund. | 400 Ω | |

| 3.01~3.2 | AT cut Fund. | 200 Ω | |

| 3.21~3.5 | AT cut Fund. | 150 Ω | |

| 3.51~3.9 | AT cut Fund. | 120 Ω | |

| 3.91~5.0 | AT cut Fund. | 100 Ω | |

| 5.01~7.0 | AT cut Fund. | 50 Ω | |

| 7.01~10.0 | AT cut Fund. | 35 Ω | |

| 10.0~30.0 | AT cut Fund. | 25 Ω | |

| 30.01~45.0 | AT cut Fund. | 20 Ω | |

| 24.0~100.0 | AT cut 3rd O/T | 40 Ω | |

| 80.0~160.0 | AT cut 5rd O/T | 70 Ω | |

| 110.0~200.0 | AT cut 7rd O/T | 120 Ω | |

| AGX-T49S / T49SS / T49S+ | 3.2~3.4 | AT cut Fund. | 300 Ω |

| 3.5~4.0 | AT cut Fund. | 150 Ω | |

| 4.1~4.9 | AT cut Fund. | 120 Ω | |

| 5.0~5.9 | AT cut Fund. | 100 Ω | |

| 6.0~8.9 | AT cut Fund. | 80 Ω | |

| 9.0~9.9 | AT cut Fund. | 60 Ω | |

| 10.0~12.9 | AT cut Fund. | 50 Ω | |

| 13.0~30.0 | AT cut Fund. | 40 Ω | |

| 24.0~40.0 | AT cut Fund. | 40 Ω | |

| 40.1~48.0 | AT cut Fund. | 30 Ω | |

| 27.0~30.0 | AT cut 3rd O/T | 150 Ω | |

| 30.1~50.0 | AT cut 5rd O/T | 100 Ω | |

| 50.1~70.0 | AT cut 7rd O/T | 80 Ω |

石英晶體諧振器(英文:quartz crystal unit或quartz crystal resonator,常簡寫成Xtal),簡稱石英晶體或晶振,是利用石英晶體(又稱水晶)的壓電效應,用來產生高精度振盪頻率的一種電子元件,屬於被動元件。

運用石英晶體上的電極對一顆被適當切割並安置的石英晶體施以電場時,晶體會產生變形。這就是壓電效應。當外加電場移除時,石英晶體會恢復原狀並發出電場,因而在電極上產生電壓。這樣的特性造成石英晶體在電路中的行為,類似於某種電感器、電容器、與電阻器所組合成的RLC電路。組合中的電感電容諧振頻率則反映了石英晶體的實體共振頻率。

石英晶體的優點是在溫度變化時,影響震盪頻率的彈性係數與尺寸變化輕微,因而在頻率特性上表現穩定。共振的特性還取決於振動模式與石英的切割角度 (相對於晶軸而言),目前常用的是 AT 切割,它的振盪是厚度剪切(thickness shear)振盪模式。 此外,在需要高精密度與穩定性的嚴格場合,石英晶體會放置於恆溫箱(Crystal oven)與吸振容器內,以防止外部溫度與震動的干擾。

石英元件具有穩定的壓電特性,能夠提供精準且寬廣的參考頻率、時脈控制、定時功能與過濾雜訊等功能。舉凡消費性產品:如數位電視。遊樂器,數位相機,手錶等;資訊產品:如個人電腦,及其週邊設備,掌上型電腦,及硬碟等;通訊產品:如行動電話,無線電電話,及呼叫器等;網路產品:如數據機,IA產品,甚至藍芽套件等皆會使用石英晶體振盪器!

是故,石英晶體振盪器在電子產品中佔有著舉足輕重的位置。